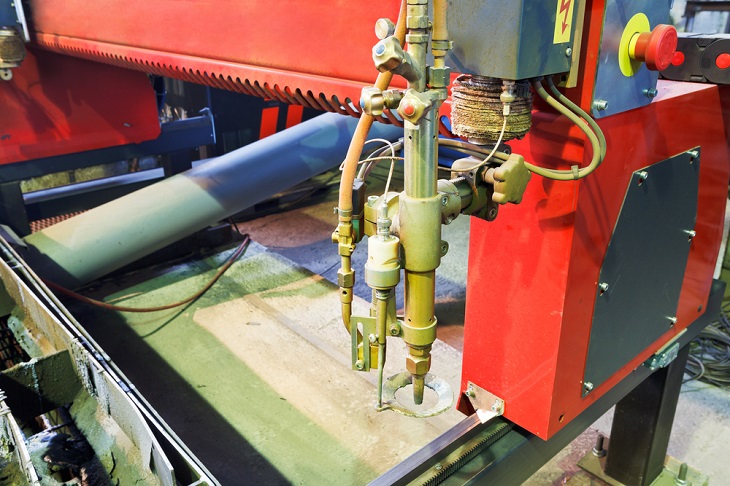

Importance of quality plasma cutting & rolling guide cannot be understated in the field of metal cutting because it can accomplish the task without any hassles. In past, OXYFUEL technology was used to shape the metals but plasma has become more popular in present time due to the simplicity of usage. The above mentioned technique can deal with all sorts of metals whether they are rusted or old. Some of the benefits of the quality plasma cutting & rolling guide for the users are as follows:

Thickness of the Metal:

- By following the instructions of the guide, one can easily handle the metals of different thickness ranging from 35mm to 2mm. Therefore, you can use different types of metals to cut them into various shapes and sizes in a seamless manner.

- Speed of the plasma cutting is quite high as compared to the conventional method. Hence, it is possible to complete the job irrespective of the complexities.

- Another advantage of the simple instructions is that the piercing speed of the plasma cutting is extremely high, and it helps to create a hole into the metal within 2 seconds.

- As a result, the productivity increases benefitting the industry to a great extent. It is possible to cut more parts within the stipulated time period.

Quality of the Work:

- Using quality plasma cutting & rolling guide is a sheer pleasure as it helps to enhance the quality by many notches. In comparison to the OXYFUEL cutting, the finesse of the plasma cutting is quite high.

- It is easier for the professionals to understand the new techniques and also to deliver better performance.

- Modern technologies incorporate nozzle shields that can focus on the target plate and deliver cuts with improved accuracy.

Various ranges of Plasma Cutting tools available in the Market:

Plasma rolling and cutting is mighty efficient in dealing with all the metals that allow electrical conduction. Some of them include aluminum, copper along with mild and stainless steel. In addition, the technique is quite handy when multiple stacks of the metallic plates have to be cut. It is devoid of any hassles and quite economical for the industry. Versatility of the technique has played an important role in making it one of the most accepted techniques in small and medium-scale heavy industries.

Simplification of the Operation:

- Minimum operator training is required to learn the plasma cutting techniques. For instance, the guide states that the stand should be not more than 1/8th of the inch to deliver high quality cutting performance.

- It is an easy task for the professionals who have worked on more complex techniques in the past. The guide also describes clearly on how to observe the safety measures while cutting the metal.

- In fact, plasma technology can be introduced to the OXYFUEL system and it works in tandem to deliver startling results to the entrepreneurs.

- One of the most important criteria for the plasma cutting to be successful is that, the equipment should be highly durable and capable to withstand increased pace of operations.

- If the metal is not strong, it can burn due to increased friction.

Reliable:

You can follow the guide because the system is reliable and simple. The number of electrical components has reduced by many notches. Hence usage is extremely simple and one doesn’t have to be a rocket scientist to understand the operational mechanism.

The technology is a shot in the arm of the industry as far as the productivity is concerned. Also If fewer parts are used to accomplish the task, it means the enterprise has to invest less in order to get better output.