Metal industry, if broken down to its elements, poses innumerable components. One of those components is temperature regulation. Furnaces play a large role in the successful execution of the same.

A furnace is a thermal closure used to mix the raw materials at high temperatures that are both in solid as well as in liquid state. Its deployment is spread across various industries like iron, steel industry, non-ferrous metal production, calcification in cement and production. The objectives of the furnace are:

- There is a need to utilize the heat in such a way that it minimizes the losses.

- Each element contributing to the unitary function is handled in a unique way; whether it is the velocity, time or temperature.

SOURCES OF ENERGY:

A.) Combustion of fossil fuels viz. solid, liquid and gases.

B.) Electric energy which includes, resistance heating and arc heating.

C.) Exothermic reaction.

HOW THE THERMAL ENERGY IS OBTAINED?

The fossil fuel contains sufficient energy. With the combustion, the potential energy is released into the products. The products of the combustion move around with the rise in the temperature.

The sensible heat is not available in the furnace. High temperature is conducive to the presence of sensible heat in the POC. This is very essential in terms of fuel utilization. Once, the furnace has been designed, the heat losses are not within the control of the room temperature.

HEAT UTILISATION:

The efficient utilization of fossil fuels can be determined by numerous factors. The potential energy of the fuel is set at 25 degree Celsius. The combustion of the energy is set at the flame temperature. The products of combustion remain in the furnace.

The heat which is carried by the combustion depends on the temperature of the furnace. Hence, the furnace heat can be recovered by installing the heater. The heat, thus obtained, is external and yet derived from internal recovery.

Hence, the heat exchanger integrates with the furnace which captures the heat and also reuses it.

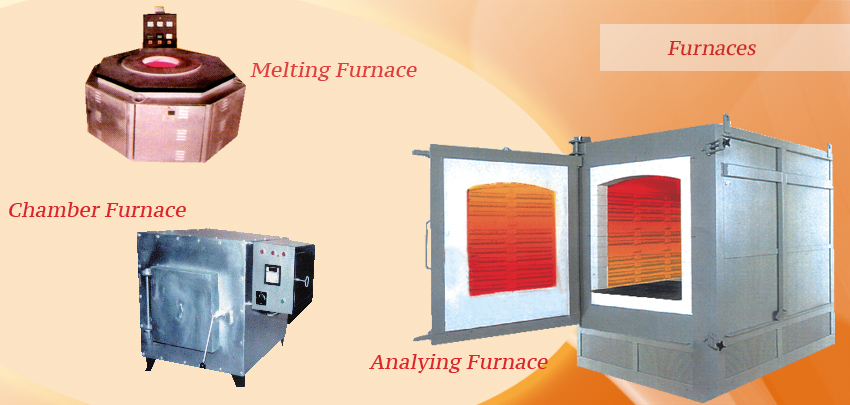

TYPES OF FURNACES:

There are two main classifications of furnaces:

- Some furnaces are generally used for the heating of the substance. The ferrous material is heated and there is a chamber that consists of preheating, soaking and heating zones. The material is fed to the preheating zone from where a flow of combustion commences in the reverse direction. The furnace design is set at the desired temperature. Then there is a continuous flow of liquid that helps in setting of lowest temperature.

- The batch furnace functions in a slightly different manner. Here, the load is heated for a fixed time and then it is discharged from the furnace before obtaining the final product.

The furnace is indispensable to manufacturers and industrial units. It is a versatile tool of machinery with multifarious uses and applications.