Forging is the best metal shaping process where metals are formed with high compression, stress and forces over it. This blog discusses some of the common applications and targeted industries that depend on forging process.

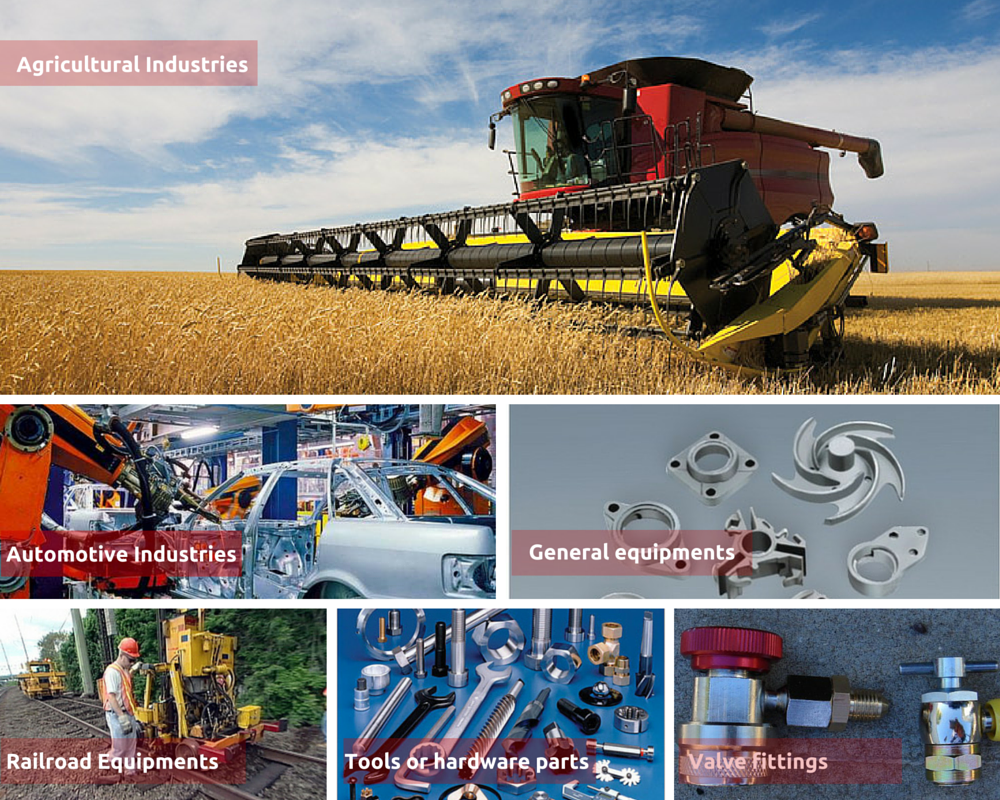

Automotive Industries

The features of forged components India are strength, reliability, and affordability that make them suitable for various automotive industries. They are suitable to work even under heavy pressure and stress. Further, it can also be used for connecting rods, different gears, shafts hubs, universal joints etc. Even copper and aluminum materials have seen great advantage in forged truck applications.

Agricultural Industries

Agricultural machines are always featured with high quality forged components with maximum strength, economical, and reliable too. They are used inside engines, gears, shafts, spindles, connecting rods, levers, or cultivator shafts etc.

Valve fittings

As we know already, forged components are prepared with heavy pressures and extreme forces. So they are acclaimed optimum solution for valves and fittings industry. They are less resistant to corrosion, and flame resistant that is taken suitable for flanges, vales, fittings, stems, saddles or elbows etc. When vales would be extra strong, they can be used under heavy pressures as well.

Tools or hardware parts

Forged components India are quality trademarks since decades. So they are widely used for manufacturing hand tools and hardware parts worldwide. Medical components can also be prepared precisely with forging process. They need extra tools or machineries to support metal shaping process for medical practice. All of the hand tools or hardware parts prepared with forging process are highly durable, corrosion resistant and efficient in use.

Railroad Equipments

The material handling equipments should always be more reliable, durable and economical in use. They are heavy duty equipments that should always be manufactured with care and utilized for wide industrial apps. They are long lasting and able to withstand even under harsh environmental conditions.

General equipments

Forging components can be designed in almost all shapes and sizes. They can be pretty much smaller or larger in size. The textile industries, chemical industries, refineries, power industries, paper industries are just few names where forged parts can be used successfully.

The applications of forging components don’t end here. It can be used for ship-building, aerospace industries, knife making etc. You just have to make sure right dimensions and size is chosen for effective implementation of product.