Greg Fischer, assistant professor of mechanical engineering, is developing robotic systems that will allow surgeons to operate with the guidance of real-time MRI (magnetic resonance imaging) images. Robots under development will precisely place electrodes for deep-brain stimulation and the insert radioactive pellets to treat prostate cancer. The interior of an MRI scanner, which uses strong magnets and radio waves, is a difficult environment for robots, which cannot be made of metal or use electronic components.

Combining magnetic field immunity with high precision motion over inches of travel, Piezo LEGS® motors walk the line.

Surgeons treating brain cancer face a conundrum: They can capture ultra-high-resolution images of the tumor using magnetic resonance imaging (MRI) or they can use ultra-precise surgical tools to remove the tumor, but they can’t do both at the same time. At least they couldn’t previously. Today, Worcester Polytechnic Institute professor Greg Fischer, is busy developing a surgical robot designed for use inside an MRI machine. Guided by real-time feedback, the robot can position a high-energy, interstitial focused ultrasound probe exactly at the tumor, delivering optimal surgical results and an ideal outcome for the patient. Of course, building a robot that can operate within the high magnetic fields generated by an MRI unit was not easy, but with sophisticated controls engineering and piezoelectric positioners from PiezoMotor, the WPI team has built a system that promises to revolutionize the treatment possibilities of MRI.

The process of designing surgical devices is rife with challenges. Systems need to be accurate and repeatable, with ultrahigh resolution. They have to be electrically quiet. Above all, they must be reliable. In the case of the MRI robot, Fischer’s team faced another enormous challenge delivering all of these characteristics in a system that can also function in multi-tesla magnetic fields.

The powerful magnetic field generated by an MRI machine makes hazards of even small ferromagnetic objects like screws, let alone, motion devices like permanent magnet motors, gearboxes, and actuators. It was obvious from the outset that the MRI robot had to be based on non-traditional actuation. The answer proved to be a piezoelectric device.

Motion in a magnetic environment

Piezoelectric actuators are based on a piezoelectric ceramic that expands under an applied voltage. The problem is that the displacement introduced by the piezo effect is only a fraction of a percent of component size, while the MRI robot required up to about 100 mm of linear travel or a continuous 360 degree rotation. The WPI team found the solution in the Piezo LEGS motors from PiezoMotor.

The units consist of a set of bimorphic drive legs that are constructed so that under an applied voltage, they flex slightly and extend. In practice, they are driven in alternating pairs so that they “walk” a drive rod forward in nanometer steps at speeds as high as 15 mm/s (or spin a disc in the case of rotary motion). Because one set of legs is the always in contact with the actuator at any time, they are inherently safe actuators (providing braking when unpowered) with the motors provide a stall force (holding force?) of up to 10 N.

The WPI robot consists of one module with X, Y, Z translation and two rotational modules that correspond to the arc angles of a head frame. Future designs will include additional of degrees of freedom to permit the insertion and rotation of cannula and stylet. To generate linear motion, the WPI team uses a combination of linear Piezo LEGS motors in a direct drive for needle insertion

and rotary Piezo LEGS motors to drive aluminum lead screws. For rotary motion, they use 3-D-printed custom pulleys and rubber- or fiberglass-reinforced timing belts.

Although the masses involved are small, the materials generate greater friction than conventional designs, which means that they require higher torque to produce motion, and the piezomotors deliver. “In a lot of applications, you can get away with a piezo motor and a direct drive or a pulley reduction of several-to-one,”Fischer says. “You don’t need 100:1 gear ratio reductions like you might need with a small DC motor.”

Piezo LEGS turned out to be the right solution for the WPI project. “There are piezoelectric actuators that will give you at best maybe 1 mm of motion,” says Fischer. “Beyond that, you’re really down to only a few companies. Of those, they sell rotary motors or they sell modules that you push up against the drive rod, but you need to actually design a whole custom device around it. In terms of a compact, self-contained, I haven’t seen any competition, really, for the PiezoMotor devices.”

Control challenges

The piezoelectric actuator requires only very small conductive electrodes that are both nonmagnetic and not ferrous. This makes it safe to use in the MRI environment. In this application, however, safe was not enough. Any electrical noise generated by power supply or drive electronics has the potential to distort the image, which would defeat the purpose. “A lot of times you’ll get static-like artifacts,” says Fischer. “Electronic noise coupled with non MRI-compatible materials can effectively warp the image and then things won’t show up where you expect them to which is a major, major problem if you’re trying to guide an intervention based on the imagery.”

Clearly, the application required specialized electronics. At the same time, the nature of the piezoelectric motor meant that it required a sophisticated drive waveform. In response, Fischer’s

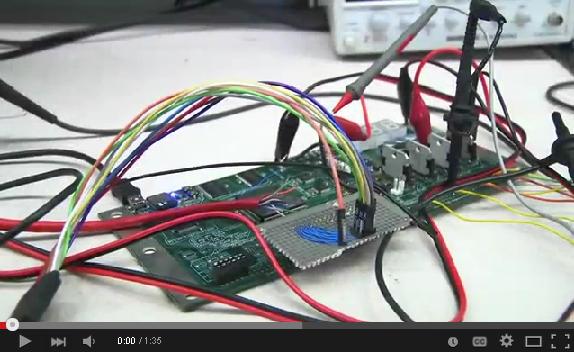

team developed a custom controls package for operating piezoelectric motors in the MRI scanner. They programmed an FPGA to adjust the relative frequency and phase of the drive signal waveforms. High-speed digital-to-analog converters deliver precise temporal control of the waveform, and highbandwidth, high-voltage linear amplifiers allow the controller to synthesize the exact drive signal needed to produce the motion. External filters remove noise, and encoder feedback enables closed-loop position or velocity control from a microcontroller running a real-time control loop on a single board. A modular backplane combines up to eight of these boards into a single shielded enclosure that resides inside the MRI scanner room with the robot. A custom cabling harness connects the controller with the robot for up to eight axes of control.

It was not a controls challenge for the faint of heart, but the project was simplified by the availability of a standalone piezo motor. “Having a reliable, ready to go closed actuator, linear or rotary, has been a big advantage,” says Fischer. “It has really let the students focus on the mechanical mechanism design and the controller design.”

The project goes beyond just the surgical robot, though. Fischer’s goal is to develop a toolbox for developing MRIcompatible robots that would incorporate sensors, actuators, controllers, amplifiers, enhanced with communication protocols. “In industry, you can buy a PLC or motor or an encoder, plug them all together, and you immediately have a working device,” he says. “There’s nothing really like that for medical devices and there’s definitely nothing close for MRI.”

To demonstrate the approach, the team is working on variations of the MRI robot for several applications including: high precision thermal ablation of deep brain cancer, deep brain stimulation electrode placement for Parkinson’s disease, and targeted MRI-guided prostate cancer biopsy and localized therapy delivery. “We’re shooting for very compact, very application specific, and they’re all based on these motors,” he says. “I have just about every piezo motor on the market in my lab. We have even tried to make our own. For us, the PiezoMotor actuators were a very good size with good force ranges, and very good torque ranges. Overall they have been very effective.”

Inside the Solution

To provide positioning capabilities in a high magnetic field, the WPI group used piezoelectric motors from PiezoMotor. Because the units came as fully functioning packages, the team could focus on the larger challenges of the project rather than building a motor. “The ability to just put them in and have them work has been really, really nice,” says Fischer. “With the most popular second alternative to their product, you have to pretty much create a custom device around it.”