Manufacturers of cooling towers consider six safety measures to disinfect their cooling towers every time. In this post, they will explain all these six precautions and will recommend their customers and clients in the industries to follow their guidelines to disinfect the cooling devices like experts.

- Run ‘online’ disinfection process instead of ‘offline’ disinfection

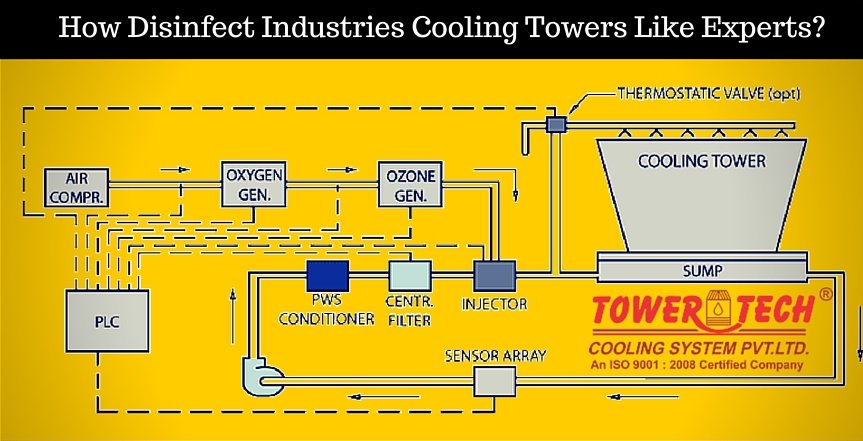

You should know that your cooling towers can be disinfected online or offline. Both the procedures are different from each other. The online process includes only chemical disinfection while the cooling tower is on operating mode. Whereas the offline process varies as you need to shut down the cooling tower and scrub it physically and disinfect it using chemicals.

The online process does not imply the physical cleaning of the cooling tower. But, it is effective in killing Legionella and is pretty cheaper, safer, and faster way. In addition, it is least corrosive. A general online disinfection basically costs to maintaining a free chlorine concentration of approx. 5 ppm for minimum 6 hours. You can find more info about the process on internet. Or else, contact Tower Tech Global professionals and ask for their assistance for the subject.

- Execute online disinfection of the cooling tower superior to cleanup it physically

Without disinfecting the cooling tower, you cannot physically clean the equipment as it will be like aggressively sweeping a dirty garage floor. What we mean is that you won’t get the cleaner cooling tower and instead a lot dust will get inhaled by you. So, cleaning the equipment physically is important. When you clean off the dirt deposits from the surfaces of the components, it becomes easier for professionals to disinfect the entire cooling tower.

- Make personal protection equipment available for the workers

Respirators will lower the risk of inhaling Legionella bacteria. It is your duty to provide the personal protection equipments to the workers for their safety. Other than respirators, there are boots, protective clothing, and goggles that protect their skin and eyes against chemicals and solutions.

- Close building outdoor air intakes within the vicinity of the device

Standard centers recommend users to close intakes within 30 meters.

- Do the things in right way

Check with companies like Tower Tech Global for the latest recommendations. You need to follow the instructions put on the chemical product labels. You need to keep the records of the procedure, including the chemicals require for the procedure, the time the chemicals need to be added to the system, chlorine, and pH test results.

Taking help of a highly experienced and qualified water treatment specialist is the best decision to ensure proper protocol is followed.

- Understand the long term limitations of the procedure

A survey conducted on Manufacturers of cooling towers in India and found that Legionella bacteria may reborn within only days after completely disinfecting a cooling tower. A program of regular maintenance, water treatment, and inspection offers better protection as compared to regular disinfection procedure. The same applies to plumbing systems and other water systems that can transmit Legionella- to implement a water management plan as per the standards.

Thank you for your time. Kindly share your thoughts with us regarding the subject we have discussed in this post.