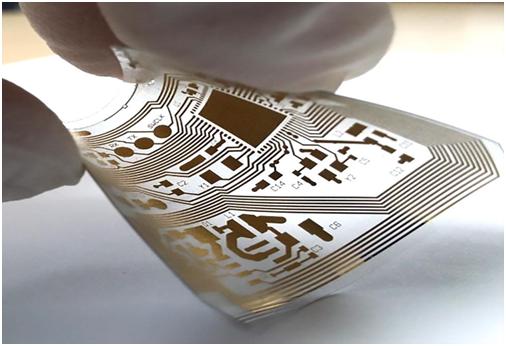

FlexEnable, the harbinger in the development and industrialization of flexible organic electronics is collaborating with Merck, the global leader in market and technology for liquid crystals and organic electronic materials. As a part of joint project, both companies have reached a path breaking stage in Plastic LCD Technology. A Plastic LCD has been developed which is free of glass material, uses organic transistors on a plastic sheet, which offers multiple benefits. Plastic LCD’s posses making of products ten times thinner, more than ten times lighter and inexpensive than glass based displays.

The benefits of this new technology, allows making twistable, light, thin & durable liquid crystal displays (LCD) possible, Application of organic transistor technology offers low cost solutions for bulk manufacturing and Concept will attract wider LC modes.

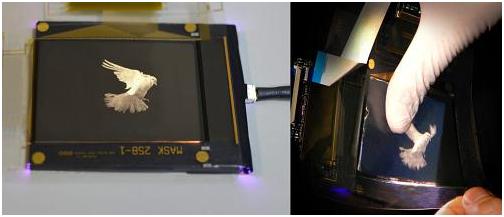

The demonstrator was developed in a shorter timeframe that combines the key benefits of Organic Transistor Technology (OTFT) including superior quality and yields. Ultimately, it throws the path for bulk manufacturing of LCD’s, the dominant in display technology in the market today. FlexEnable has now demonstrated the world’s first plastic LCD with active matrix-in-plane switching (IPS). It uses FlexEnable’s OTFT array as well as liquid crystal (LC) and organic semiconductor materials from Merck. While these demonstrators employ an IPS mode, this concept will be equally attractive for many other LC modes and applications such as e-readers, dynamic public signage and advertising.

Indro Mukerjee, Chairman of FlexEnable, acknowledges the need of Plastic LCD’s, states that “I appreciate and congratulate the FlexEnable team and partners for demonstrating the best example of maturity and advancement of our transistor platform is. To achieve this within months rather taking years is a testament to the depth of understanding and IP we have across our toolkit of industrially proven processes. Plastic LCD’s bring clear benefits where weight and thickness is the key, including volume consumers and industrial markets. It also offers a route to simplify, lower cost of device stacks for display makers”.

With this path breaking innovation future seems to be promising with less consumption of conventional glass based LCD’s and more usage of plastic based LCD’s that isn’t fragile in nature, ensures better dynamics and durability in display technology. Throwing opportunities to many players in the market.

Source: http://www.Plastics-technology.com